Mission

To emerge as a world-class foundry by ensuring excellence in quality, delivery and service. Be the No#1 dependable source for our customers.

Vision

To help our customers grow their businesses by supplying high-quality castings supported by outstanding customer services.

What We Do

SAND CASTING

NDT

MACHINING

Certifications

ISO 9001:2015 Certified

PED 2014/68/EU,

AD 2000 – Merkblatt W0

NORSOK M-650, API20A Compliance

Location

We are located in Coimbatore, India. Coimbatore is well connected by air. The nearest sea port is Cochin which is only approx. 200 kms away.

Materials

We have the capability to pour over 40 alloys.

How We Do It

Engineering and Design

Pattern Making

Molding

Melting

Fettling and Finishing

Casting Upgrade

Testing and Laboratories

Machining

3D Printed Molds & Cores

Quick Ship Program

- Our Quick Ship Program is the ideal choice for our customers for their quick turnaround service orders as well as urgent project orders.

- Quick Ship orders are handled separately from the regular orders.

- A separate Quick Ship Team tracks the orders on priority right from Day 1.

- Lead times starting from as low as 14 days.*

* For approved patterns and material grades. Subject to review during PO receipt

New initiatives for 2024

- ERP (SAP) currently under implementation.

- Maximum utilization of Green energy for the foundry processes.

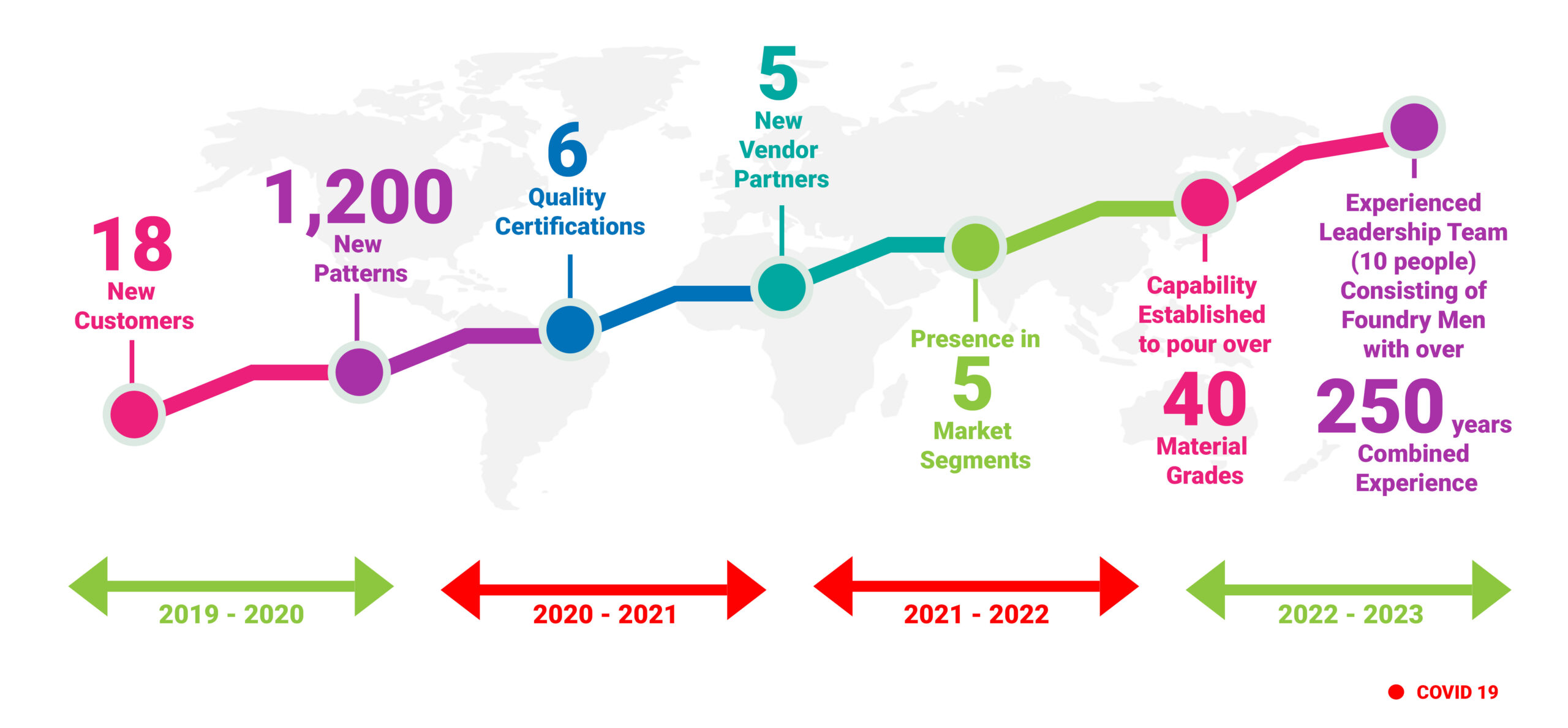

Our Milestone

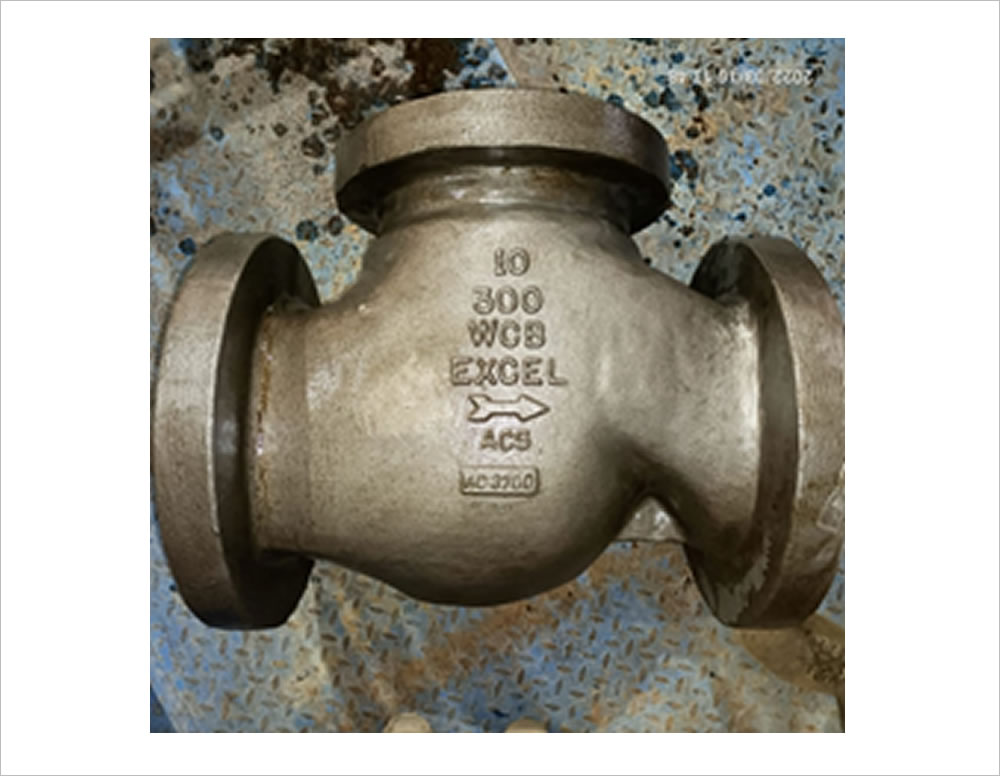

OUR Products

Materials

Fabrication

to Casting Project

▪ Specializing in taking on fabrication to casting

projects for customers.

▪ Substantial cost savings and capacity enhancement

for customers.

▪ Involved right from casting design to delivering the

product.